When Should 3D Printing Drive Business to the Automotive Sector?

The automotive sector is driven by the need for quality parts, delivered in a timely fashion, and at a competitive price. As such, for some applications, 3D printing is a good fit, allowing the manufacture of complex geometries in a speedy and cost-effective fashion. Here, experts at 3DPRINTUK and Wiesner Design discuss when, and even if, 3D printing would be the right choice for a particular auto part.

3DPRINTUK works with a number of automotive OEMs and tier 1 and 2 supply chain companies producing both prototypes and small batch production runs using different powder bed fusion (PBF) technologies for a wide variety of applications.

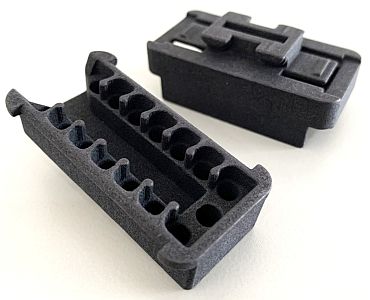

Electrical connector housings found in older Porsches. The originals tend to become brittle after decades of use whereas the modern PA12 version won't suffer the same fate.

One of those companies, Wiesner Design, combines a passion for classic Porsches and additive manufacturing (AM) to bring rare and no-longer-available parts back to life. Wiesner Design focuses on items that are uneconomical to injection mould in low volumes, especially where complex geometries are involved. In all cases the company employs AM to produce parts as good as the original or indeed sometimes better.

Recently, Nick Allen, Managing Director at 3DPRINTUK, caught up with the owner of Wiesner Design, Martin Wiesner, to discover his views on 3D printing and how he uses the technology. Here is an edited portion of their conversation.

Allen: Explain what it is you do at Wiesner Design, how long you have been using 3D printing as a technology, and what you use it for?

Wiesner: I design and manufacture parts for the automotive aftermarket and electric vehicle conversion industries. Because of my long history with air-cooled Porsches most of what I do is centred around classic 911 models and their racing derivatives. This ranges from recreating no-longer-available parts for old Porsches to the integration of modern technologies into such cars. I bought my fist printer in 2016. It was a somewhat primitive second-hand model but opened my eyes to what's possible. At the time 3D printing was viewed by many as a hobby or, at best, a prototyping tool. However, I had other ideas and started experimenting with exotic materials to make end-use parts first for my own car, then later for friends and eventually it became a business. I use 3D printing to produce non-structural or semi-structural automotive components that go into various parts of a car.

Part of the early Porsche 911 control box. The complex geometry and thin walls make FDM printing difficult but powder-based printers make short work of it.

Allen: There are numerous 3D printing processes available today for both prototyping and production applications. Which processes are best suited to which applications?

Wiesner: I follow quite an elaborate decision tree when considering how to manufacture a part. The very first thing to keep in mind is that not everything can be 3D printed and not everything that can be 3D printed should be 3D printed.

The main factors I base my manufacturing decisions on are strength, heat resistance, surface finish (including detail) and cost. Strength could be divided into impact strength, tensile strength, and more, but to keep it simple let's just ask whether this is a part that needs to be strong, heat resistant and not brittle. A bracket that goes into the engine bay of a rally car needs to be very strong, heat resistant, and obviously cannot be brittle. This eliminates resin as a solution because heat resistant resins tend to be brittle, and impact resistant resins can't handle heat. The remaining choice is between Fused Deposition Modeling (FDM), MultiJet Fusion (MJF) and/or Selective Laser Sintering (SLS).

Now the shape becomes a factor. Could this part be printed strongly and neatly on an FDM machine? This is normally a cheaper option than MJF/SLS and yields a lighter end result. Unfortunately, unless a part was specifically designed for FDM printing, chances are good that it won't be neat and strong at the same time. FDM has three weaknesses: first, it easily breaks along layer lines; second, it may require support structures to print which results in rough looking overhangs; and third, it's hard to overlook those amateur-looking layer lines. If none of this is a problem, then FDM is the way to go. However, I always first check what MJF/SLS would cost. Sometimes the price difference doesn't warrant the effort of FDM printing and I end up using MJF/SLS anyway, enjoying the bonus of a professional looking part which is stronger than FDM.

If a part is customer facing (which includes mechanics, racing drivers and bystanders peeking into engine bays) it becomes very hard to justify FDM unless the part geometry lends itself towards a neat and strong print at the same time. In many cases it's worth the extra cost to have such a part MJF/SLS printed to get a strong and visually appealing end result.

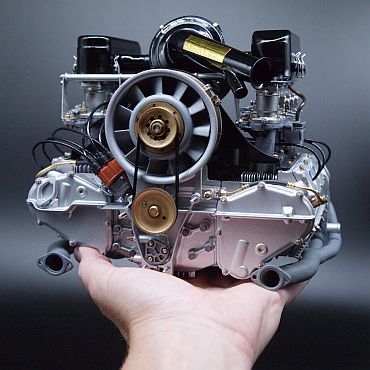

A super accurate scale model of the very first Porsche 911 engine ever produced. Almost everything in the photo is SLA printed, including the tiny little nuts and spring clips on the air box. The fan belt is printed by 3DPRINTUK.

Wiesner adopts a pragmatic view of 3D printing and maintains that AM as a technology doesn't magically replace all the old tools in the toolbox. Instead, it's an incredibly powerful new tool that complements the existing tools in ways never thought possible. Wiesner's advice to any manufacturer is to reach out to an expert who understands the technology from a production perspective, not only as a prototyping tool, and see how it could complement what you are already doing.

For Wiesner, the beauty of AM is its agility, meaning it can be phased in easily and cost effectively by first targeting low-hanging fruit in your business. It usually starts with something as simple as a jig or fixture which would be somewhat tricky to make otherwise, or finally trying out that oddly shaped item that your development team or engineers have been shying away from. That's how Wiesner ended up designing and manufacturing parts for some globally respected Porsche tuners and manufacturers, by helping them test the water first and showing them a glimpse of what's possible. After that, the technology finds its own way into existing and new projects.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::